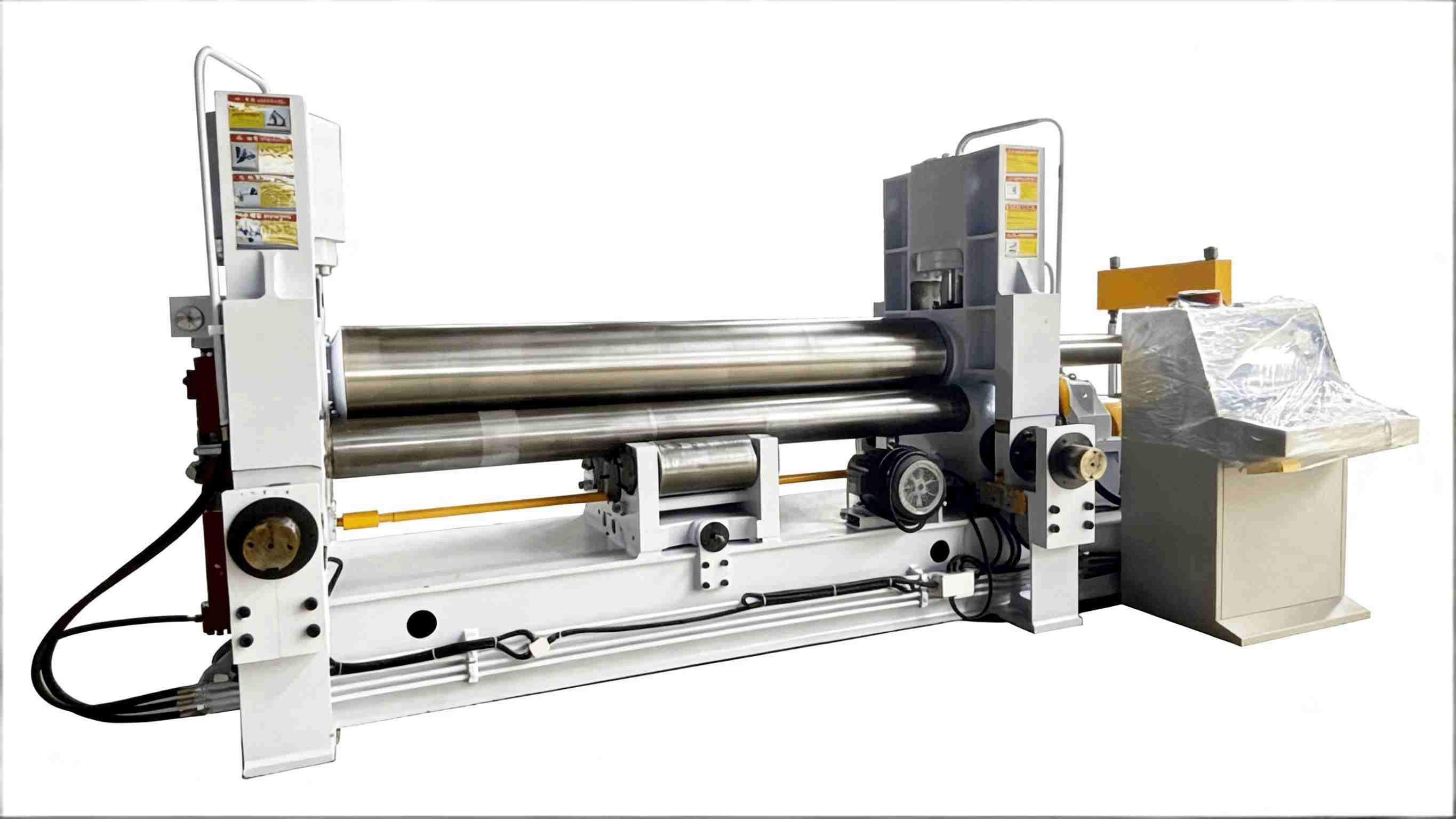

Working Principle and Structural Features of the Top-Roll Universal Plate Bending Machine

The top-roll universal CNC three-roll plate bending machine incorporates technology introduced from Japan. After years of domestic development, it is now widely used across various industries. Below, I will outline the composition of this CNC three-roll plate bending machine. The main body consists of the main drive components, horizontal movement components, top roll components, support roll components, tilting components, left and right frames, base, and balancing devices.

1. Main Drive System

Located on the right side of the machine, it comprises the main motor, pulley, reducer, and output gear.

The system supports forward and reverse rotation to deliver working power. Torque is transmitted through the main reducer, output gear, and lower roller gear to rotate the lower roller. Friction then drives the plate feed, completing the rolling process.

2. Lower Roll and Horizontal Movement Components

The lower roll assembly comprises the lower roll, lower roll bearing housing, lower roll shaft sleeve, and lower roll gear.

The lower roll is fabricated from high-quality carbon steel, undergoes full quenching and tempering, with a surface hardness of HRC 48–55.

The horizontal movement mechanism is powered by a horizontal drive motor. Through a worm gear transmission and a screw transmission mechanism, it drives the frame and upper roll assembly to move horizontally, enabling the pre-bending of the workpiece.

3. Upper Roller Assembly

Comprises a hydraulic cylinder, bearing housing, bearings, and upper roller.

The upper roller is drum-shaped to compensate for partial deflection caused by deformation.

Manufactured from 42CrMo steel with quenched and tempered treatment, the roller surface hardness is HRC 56–62.

4. Idler Assembly

Comprising the support roller assembly, inclined wedge mechanism, and screw mechanism.

The adjustment screw drives two sets of opposing inclined wedges to converge or separate, thereby raising or lowering the support roller assembly.

The support rollers are manufactured from 45 steel and undergo quenching and tempering treatment.

5. Tipping Device

Comprising pins, slide ram, tipping hydraulic cylinder, and support brackets.

Activation of the tilting hydraulic cylinder drives the tilting frame to tilt and reset. During tilting, workpieces can be removed axially from the tilting end.

6. Frame

Comprises the frame body, slide plate, and bushings.

The frame body is a welded component, annealed and shot-peened. It mounts the main hydraulic cylinder and drives the upper roller assembly for horizontal movement.

7. Base

Box-type welded structure, annealed and shot-peened. Used for mounting various components.

8. Balancing Device

Comprising a crossbeam, support plate, tie rods, etc.

Used to press down the tail end of the upper roll, maintaining balance after the tilting frame tilts to facilitate workpiece removal.

Ready to Optimize Your Production Line?

Contact us now for a free technical consultation and customized quote on CNC plate bending solutions.

Five Tips for Selecting the Right Shearing Machine

Five Tips for Selecting the Right Shearing Machine

Which manufacturer offers the best large-scale plate rolling machines?

Which manufacturer offers the best large-scale plate rolling machines?

Working Principle and Structural Features of the Top-Roll Universal Plate Bending Machine

Working Principle and Structural Features of the Top-Roll Universal Plate Bending Machine

Analysis of Types of Three-Roll Plate Bending Machines

Analysis of Types of Three-Roll Plate Bending Machines